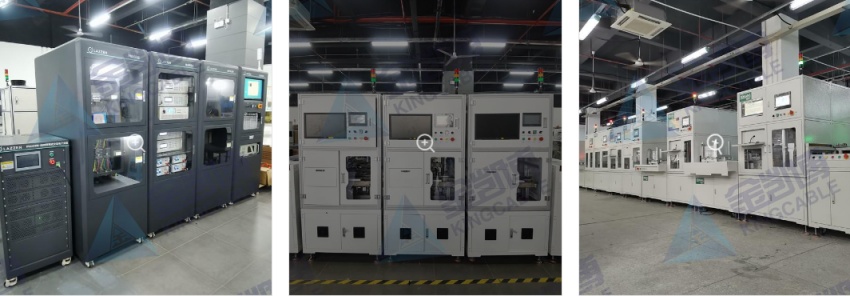

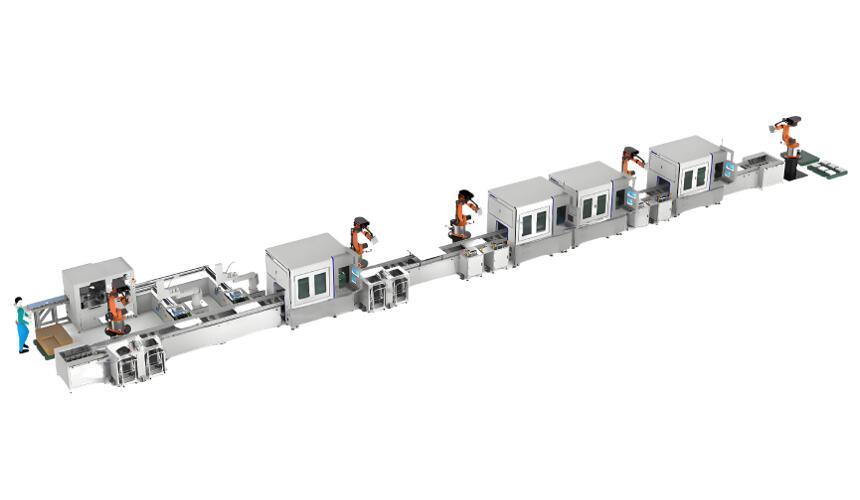

Production line function

Feeding system: usually with vibration plate, silo and other equipment, which can automatically transport various parts of WIFI module, such as PCB board, chip, antenna, shell, etc., to the assembly starting position in a specific order and direction to ensure the accuracy and efficiency of feeding.

Assembly system

Glue dispensing station: completed by glue dispensing machine, can accurately apply appropriate amount of glue on PCB board and other parts, used to paste chips and other components to ensure the stability of connection.

Placement station: with the help of placement machine, tiny electronic components such as chips, resistors, capacitors, etc. are accurately placed on the designated position of PCB board, and the placement accuracy can reach micron level.

Welding station: such as reflow soldering equipment or laser welding equipment, through heating to melt the solder, realize the electrical connection and mechanical fixation of components and PCB board, and ensure the quality and reliability of welding.

Assembly station: use robotic arms and other equipment to assemble antenna, shell and other parts with PCB board on which electronic components have been assembled to form a complete WIFI module.

Test system

Functional test station: By connecting the test instrument, the basic functions of the WIFI module are tested, such as whether it can send and receive signals normally, whether it supports different network protocols, etc.

Performance test station: Use professional equipment such as spectrum analyzer and network tester to accurately measure the performance indicators of the WIFI module such as signal strength, frequency stability, transmission rate, anti-interference ability, etc.

RF test station: Mainly test the RF performance of the WIFI module, including the detection of parameters such as transmission power, receiving sensitivity, frequency error, etc., to ensure that it meets relevant standards and specifications.

Unloading system: It includes unloading conveyor belt and sorting mechanism. According to the test results, qualified WIFI modules and unqualified products are transported to different areas for subsequent packaging or repair processing.

Working Principle

The control system with PLC (Programmable Logic Controller) or industrial computer as the core coordinates and manages all parts of the production line. The staff sets the assembly process, test parameters and production rhythm in the control system in advance. The system drives the equipment of each station to work in sequence according to the set program, realizing a fully automated production process from loading, assembly to testing and unloading of parts. During the production process, the sensor monitors the working status and material conditions of each station in real time, and feeds back the information to the control system so that the system can make adjustments and decisions in time to ensure the smooth progress of production.

Functional Features

High degree of automation: greatly reduces manual operation, not only improves production efficiency, but also reduces errors and quality problems caused by human factors, and can achieve 24-hour uninterrupted production and increase production capacity.

High-precision assembly and testing: It can ensure the high precision and consistency of component assembly. At the same time, the test system can accurately measure and evaluate the various performance indicators of the WIFI module to ensure that the product quality meets strict standards and requirements.

Data recording and tracing: Automatically record the assembly and test data of each WIFI module, such as assembly time, test results, parameter information, etc., to facilitate product quality traceability and quality control of the production process, and help analyze the causes of product failures and improve production processes.

Flexibility and scalability: The assembly and testing processes can be flexibly adjusted according to different production needs and product models. By adding or replacing workstation equipment, the function expansion and upgrade of the production line can be achieved to adapt to market changes and product technology development.

Application Fields

It is mainly used in the mass production of WIFI modules in the communication equipment manufacturing and consumer electronics industries, such as the production and manufacturing of WIFI modules used in mobile phones, tablet computers, wireless routers, smart home devices and other products, providing stable and high-performance WIFI connection function guarantee for these products.

—————————————————————————————————————————————————————————

Hello! The above product information only lists some of the main test functions. All items supported by the equipment are not listed in detail here.

If you need to obtain customized solutions or company introduction materials, please contact mobile phone & WeChat: +86 18033069200

Click the picture below to view more customer cases