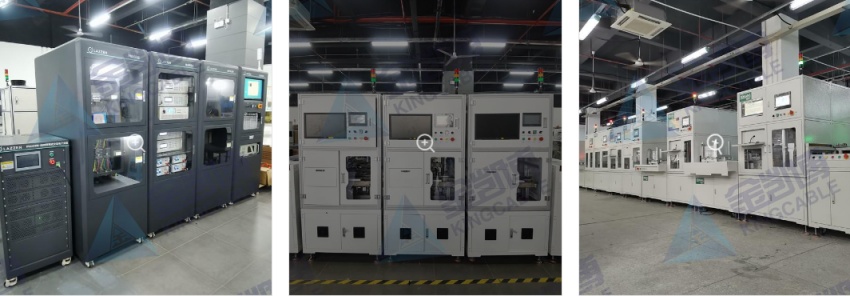

Equipment Composition

This system mainly includes five parts: high and low temperature test chamber, power supply system, load system, data monitoring system, and product communication system. Each part is designed independently and connected by a quick connector in the middle, which is convenient for maintenance and replacement. The system can test 24 products at a time, and the number can be customized according to customer needs.

Equipment Introduction

This equipment is mainly tailored for inverter products to simulate the working environment of the product, realize the high and low temperature aging test of the product after power on, and monitor and record the input and output voltage/current/power and communication in real time during the aging process. If the monitoring data is abnormal, an alarm prompt is required, which can provide accurate and reliable data support for product performance verification and quality. It is suitable for air conditioner outdoor unit panels, variable frequency compressor control panels, inverters, etc.

Equipment Features

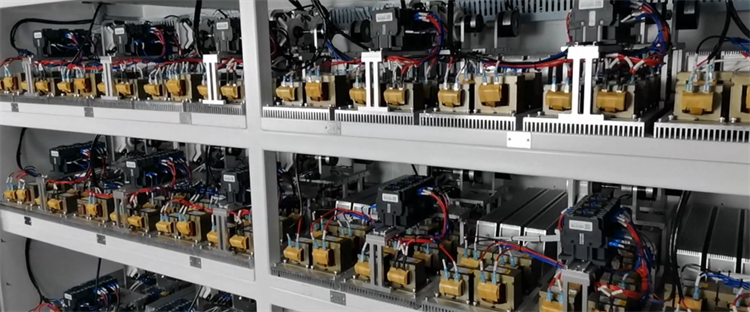

1、The high and low temperature test chamber is divided into two parts: the constant temperature zone and the front and back of the load zone. The constant temperature zone is a multi-layer structure with heating and heat dissipation functions to ensure temperature uniformity. The load zone has forced air cooling circulation to ensure that the temperature of the load system is reasonable;

2、The temperature control system adopts PID control mode, and the multi-layer constant temperature zone has input and output and communication board connection interface;

3、The load system adopts a customized press motor to simulate the load, and uses Jinkaibo's unique simulation press technology to achieve custom switching load and verify the reliability of the PFC circuit;

4、Data monitoring: real-time voltage, current, power acquisition, real-time product communication interaction, can obtain various product states, fault conditions, abnormal conditions alarm and stop the corresponding workstation;

5、Modular design, easy maintenance, safety circuit design, one-button power-off function, high safety; 6. Monitoring data is automatically recorded and saved, and data reports are automatically exported and analyzed;

6、Support MES client selection to achieve test data and factory data interaction.

FCT functional test content (pre-aging process)

(1) Control board communication protocol test (self-test fault detection)

Test description: | UART communication protocol |

Test method: | Relay control simulates fault, communication reads fault code, customer needs to provide communication protocol |

Testing tools: | RS232 Module |

Remark: |

(2) DC voltage detection()

Test description: | DC circuit part (high current part) of the product under test |

Test method: | The computer controls the current acquisition card to collect the electrical signals of the corresponding ports and make analysis and judgment |

Testing tools: | KC8000 system AC current test module, relay module |

Remark: | Each board needs to reserve 2 functional output ports, and each channel can test DC 340V , DC 200V and DC 165V |

(3) DC voltage detection (weak current part)

Test description: | DC circuit part (weak current part) of the product under test |

Test method: | The computer controls the current acquisition card to collect the electrical signals of the corresponding ports and make analysis and judgment |

Testing tools: | KC8000 system AC current test module, relay module |

Remark: | Each board needs to reserve 48 channels |

(4) AC voltage detection

Test description: | AC voltage part of the product under test |

Test method: | The signal to be tested is introduced into the AC voltage channel KC8000-HDM-ACV of KC8000 , and the data is uploaded to the PC |

Testing tools: | KC8000 system AC voltage test module, relay module |

Remark: | Each board needs to reserve 16 functional output ports, and each channel can test AC 220V , AC 127V and AC 110V |

(5) Stepper motor, frequency detection

Test description: | Frequency and timing test part of the product under test |

Test method: | The signal to be tested is introduced into the DAQ acquisition channel of KC8000 , and the data is uploaded to the PC for analysis and judgment. |

Testing tools: | KC8000 system DAQ acquisition module |

Remark: | Detecting stepper motor timing |

(6) LED/ digital tube test ( extension structure reserved , no hardware required )

Test description: | LED on/off test of the product to be tested |

Test method: | Use DAQ+photoresistor to detect whether it is lit; camera+optical fiber test (second solution) |

Testing tools: | KC8000 system DAQ test module, photoresistor module, camera |

Remark: |

(7) Control Channel

Test description: | Simulated buttons and controls of the product under test |

Test method: | 4 panels need to be controlled . Each panel needs to reserve 12 button control ports, 2 door switch control ports , and 1 empty water level and full water level control port (the water level connection line consists of three wires). Each test UUT reserves 48 relay control channels. |

Testing tools: | KC8000-RS24 for KC8000 system |

Remark: |

(8) Printing function (optional)

Test description: | Can print relevant information of test defective products. |

Test method: | During the test process, when the test conclusion is bad, the computer automatically prints the test defective product information. |

Testing tools: | printer. |

Remark: | This function can be canceled after selecting the display |

—————————————————————————————————————————————————————————

Hello! The above product information only lists some of the main test functions. All items supported by the equipment are not listed in detail here.

If you need to obtain customized solutions or company introduction materials, please contact mobile phone & WeChat: +86 18033069200

Click the picture below to view more customer cases