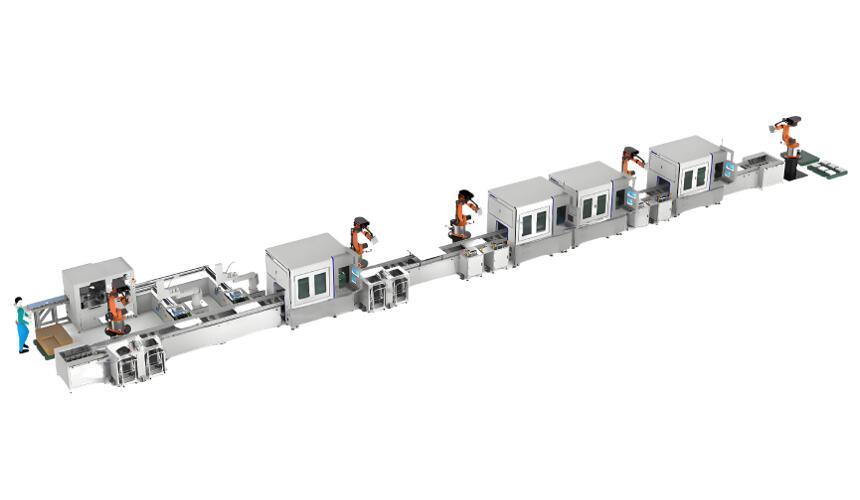

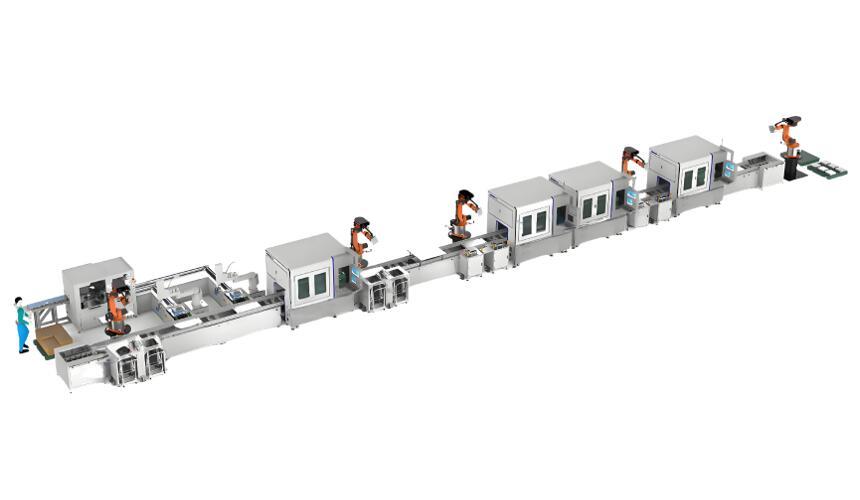

Working Principle

The square shell battery enters the production line from the warehouse through the feeding system, and first passes through the assembly system for welding, assembly and other operations to form a battery module. Then, the battery module enters the detection system, and various performance tests are carried out in turn. The test data is transmitted to the control system in real time for analysis and judgment. For modules that pass the test, they enter the PACK system for subsequent processing such as BMS installation and packaging; for unqualified modules, they will be transported to the designated area for repair or scrapping. Under the unified coordination of the control system, the entire production process is closely coordinated in all links to realize the automated production of square shell battery module Pack.

Main components

Feeding system: including battery feeding mechanism, battery cell buffer area, etc., which can realize automatic feeding and temporary storage of square shell batteries, ensuring that the batteries can enter the production line accurately and orderly. Some feeding systems also have battery cell scanning and detection functions, which can perform preliminary inspections on the basic information and appearance of the batteries.

Assembly system

Laser welding station: laser welding technology is used to weld the poles and connecting plates of square shell batteries with high precision to ensure a firm connection and good conductivity. The welding process is precisely controlled by robots or automated welding equipment to ensure the consistency of welding quality.

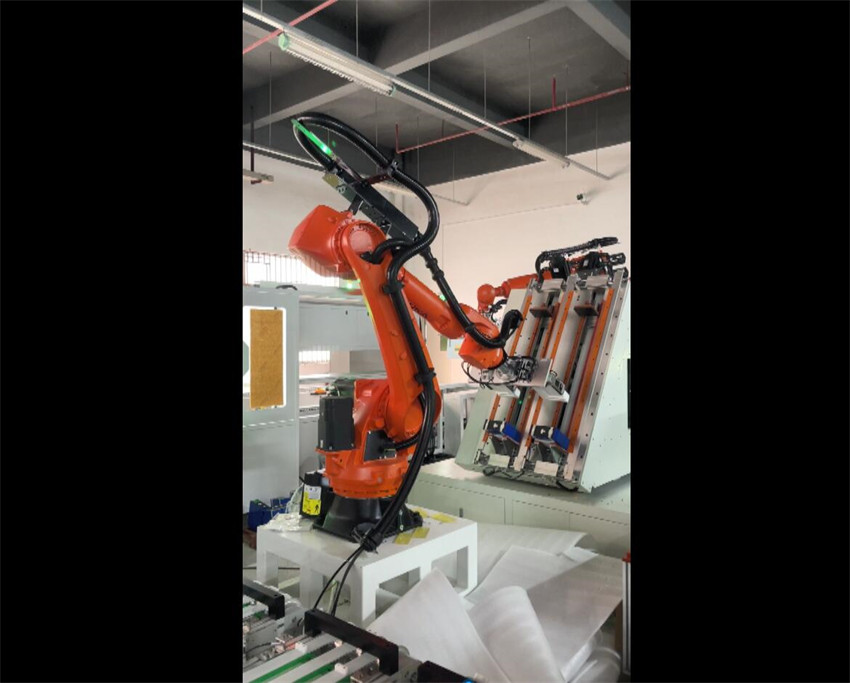

Module assembly station: through automated devices such as robotic arms, the batteries are arranged and stacked according to the design requirements, and fixed brackets, insulating materials, etc. are installed to form the basic structure of the battery module. At the same time, some auxiliary components may also be installed at this station, such as temperature sensors, voltage acquisition lines, etc.

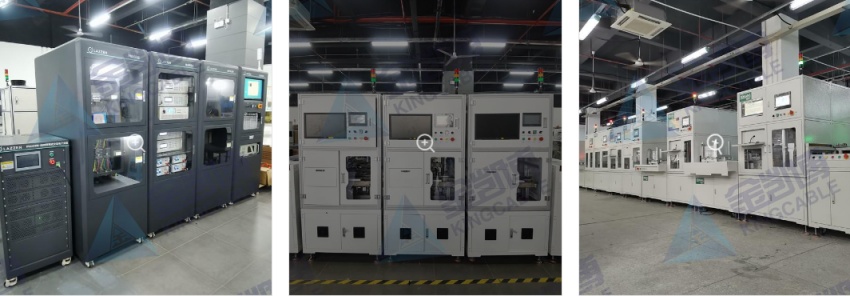

Detection system

Voltage and internal resistance detection station: professional detection equipment is used to measure the voltage, internal resistance and other parameters of each battery module to ensure that it meets product standards. Once an abnormal parameter is found, the system will automatically mark it and transport the module to the repair or rework area.

Insulation detection station: Test the insulation performance of the battery module to prevent safety hazards such as leakage. Usually, equipment such as insulation resistance testers are used to measure the insulation resistance between the positive and negative poles of the module and the shell.

Appearance inspection station: Use a visual inspection system to check the appearance of the battery module, including welding quality, whether the components are installed in place, and whether there are scratches on the surface. The module image is captured by an industrial camera and compared with the standard image for analysis to achieve automated appearance defect detection.

PACK System

Battery management system (BMS) installation station: Install the BMS on the battery module, and make electrical connections and functional debugging. The BMS is the core control component of the battery module, responsible for monitoring and managing the status of the battery to ensure the safety and performance of the battery.

Module packaging station: Pack the qualified battery modules, usually including labeling, film covering, coding and other operations to provide protection for the battery module and identify product information.

Control system: With PLC or industrial computer as the core, the operation of the entire production line is monitored and scheduled through the written control program. Operators can set production parameters and production plans through the human-machine interface, view equipment operation status and production data, etc. At the same time, the control system also has fault diagnosis and alarm functions, which can stop the equipment in time and prompt fault information when a fault occurs, making it convenient for maintenance personnel to investigate and repair.

Performance Advantages

Improve production efficiency: The automated production process greatly reduces the manual operation links, can achieve 24-hour uninterrupted production, effectively improve the production efficiency and output of battery modules, and meet the needs of large-scale production.

Ensure product quality: Through high-precision automation equipment and advanced detection technology, it can ensure the stable and reliable quality of each battery module, reduce the impact of human factors on product quality, and improve product consistency and qualified rate.

Reduce production costs: Reduce labor costs and waste losses caused by human errors. At the same time, the efficient operation of the automated production line also reduces the energy consumption and material loss of unit products, thereby reducing the overall production cost.

Improve production safety: In the battery production process, some dangerous processes are involved, such as laser welding. The automated production line can isolate operators from dangerous processes, reduce the safety risks of operators, and improve the safety of the production process.

Application Areas

Widely used in new energy vehicle manufacturers, battery manufacturers, etc., providing high-performance and high-quality square shell battery modules for new energy vehicles, electric motorcycles, energy storage systems, etc. With the rapid development of the new energy industry, the demand for square shell battery modules continues to increase. The square shell battery module Pack automated production line plays an important role in promoting the development of the new energy industry.

—————————————————————————————————————————————————————————

Hello! The above product information only lists some of the main test functions. All items supported by the equipment are not listed in detail here.

If you need to obtain customized solutions or company introduction materials, please contact mobile phone & WeChat: +86 18033069200

Click the picture below to view more customer cases