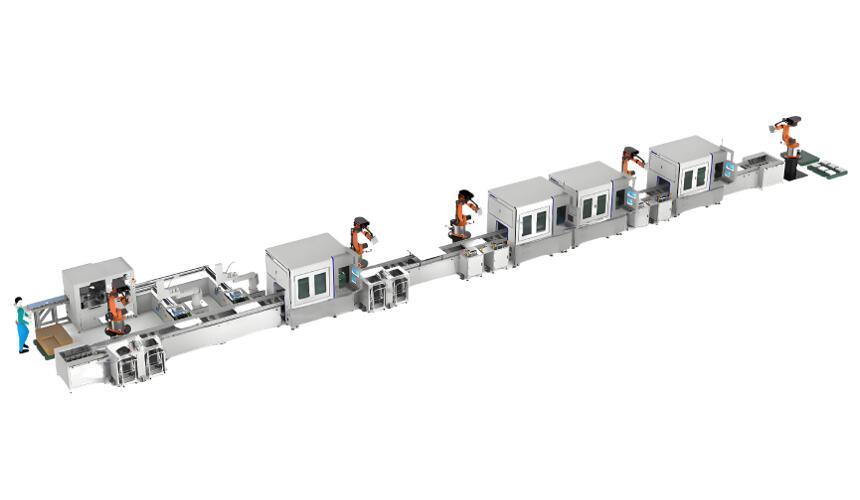

Production Line Design Concept

1. Optimal site layout: Combined with site, process, production capacity and other requirements, design a comprehensive and optimal site layout plan;

2. Optimal logistics path: Design the best logistics path to achieve timely and efficient logistics between the warehouse and each production process;

3. Automated production: Production operations can achieve automated production to the greatest extent possible, reducing worker operations;

4. Easy maintenance of equipment: Reflects the maintainability design of the equipment, and the daily maintenance of the equipment is fast, convenient and simple;

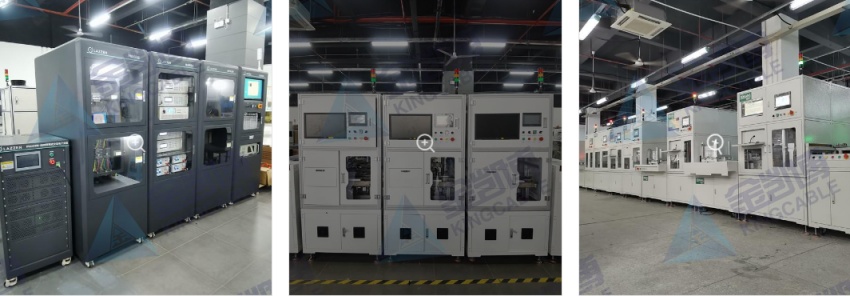

Production Line Features

1. Conveying: Responsible for conveying the fixture to each workstation for operation, and after completion, the fixture will be returned to the initial workstation to realize the function of automatic circulation of the fixture;

2. Fixture: ICT, FCT, and burning test fixtures can be configured according to the process and size characteristics of the customer's products, and then the main interface of the equipment can be selected from 1 to 1 to 4 modes;

3. Sorting: The robot automatically removes the PCB board from ICT, take out the fixtures after burning, scan the barcode information, sort out the product status, put the defective products into the recycling station, and the good products into the next station;

4. Transplantation: The fixture is transferred to each FCT station by a transplanter or a manipulator to scan the barcode for testing. When the previous machine to be tested is tested, the next machine to be tested automatically flows to the next vacant FCT station for testing;

5. Software: Self-developed measurement and control software, display the test status of each test slot through the terminal display, including equipment operation status, equipment capacity, actual capacity, test efficiency, equipment utilization rate, equipment failure statistics within the cycle, pass rate, retest rate and other key information;

6. Manual position: The design of the manual position mechanism is ergonomic, easy and fast to take and put, and the front, back, left and right transfer distance is controllable;

7. Heating test (optional): After the PCB is loaded, it is first tested at room temperature on the normal temperature platform, and then enters the two preheating furnaces in turn through the conveyor belt to preheat the PCB board twice, and finally performs FCT high temperature test in the high temperature furnace, and sorts OK boards and NG boards after coming out.

—————————————————————————————————————————————————————————

Hello! The above product information only lists some of the main test functions. All items supported by the equipment are not listed in detail here.

If you need to obtain customized solutions or company introduction materials, please contact mobile phone & WeChat: +86 18033069200

Click the picture below to view more customer cases