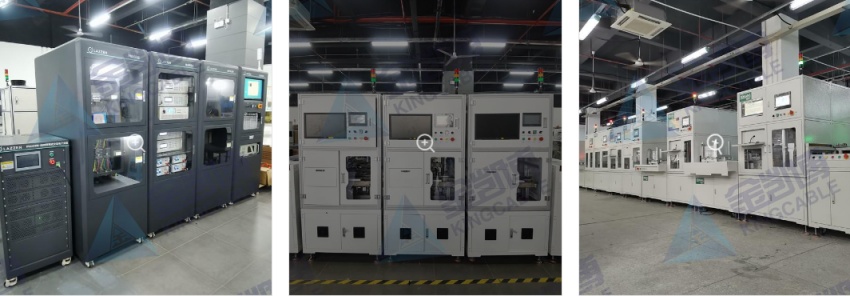

"Offline FCT test system" is a device commonly used for functional testing of electronic products

Basic Meaning

"Offline" means that the test system is not connected to other equipment on the production line in real time, and can complete the test task independently, with certain flexibility and autonomy. "Dual station" means that the system has two test working positions, which can test two tested products simultaneously or alternately to improve test efficiency.

Structural Composition

Test station: contains two independent test areas, each station is equipped with a special test fixture to fix the tested product and realize electrical connection with the product to ensure accurate transmission of test signals.

Test instruments: such as power supply, signal generator, oscilloscope, logic analyzer, etc., provide various excitation signals required for testing, and measure and analyze the output response of the product.

Control system: responsible for coordinating the test process of the two stations, controlling the working status of the test instruments, sending instructions, collecting data according to the preset test procedures and parameters, and judging and processing the test results.

Operation interface: generally a touch screen or computer interface, through which operators can set test parameters, select test procedures, view test results, and other operations to achieve human-computer interaction.

Working Principle

The system connects the tested product to the test instrument through the test fixture, inputs various excitation signals simulating the actual working state to the tested product according to the preset test plan, and then collects the output signal of the product. The control system compares and analyzes the collected output signal with the standard correct signal, and judges whether the function of the product is normal, whether there is a fault or defect based on the comparison result.

Main Features

Efficiency: The dual-station design enables the system to test two products at the same time. Compared with the single-station test system, it can complete the test of more products in a unit time, which effectively improves the test efficiency.

Flexibility: The offline working mode makes it not restricted by the production line. It can be moved and deployed at any time according to the actual test needs, and is suitable for different production environments and test tasks.

Accuracy: Equipped with high-precision test instruments and advanced test algorithms, it can accurately detect various functional problems of the product and ensure the reliability of the test results.

Scalability: The system usually has good openness and scalability. According to the changes in product testing requirements, it is easy to add or replace test instruments and upgrade test software to meet the testing requirements of different types of products.

Application Scenarios

Widely used in the functional testing of various electronic products in the electronics manufacturing industry, such as mobile phones, tablet computers, laptops, smart wearable devices, etc., in the research and development stage and the random inspection or full inspection during the production process, which can timely discover product functional defects, improve product quality, and reduce production costs.

—————————————————————————————————————————————————————————

Hello! The above product information only lists some of the main test functions. All items supported by the equipment are not listed in detail here.

If you need to obtain customized solutions or company introduction materials, please contact mobile phone & WeChat: +86 18033069200

Click the picture below to view more customer cases