Introduction

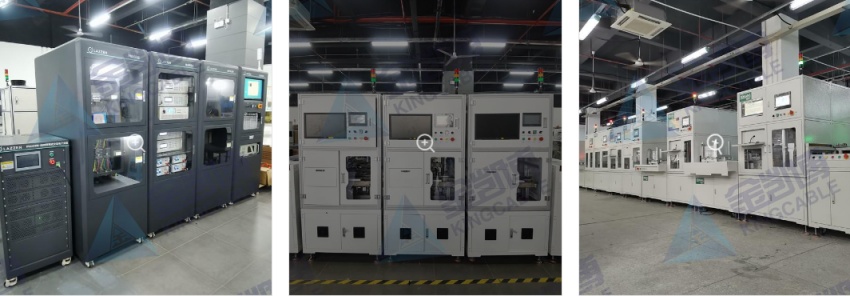

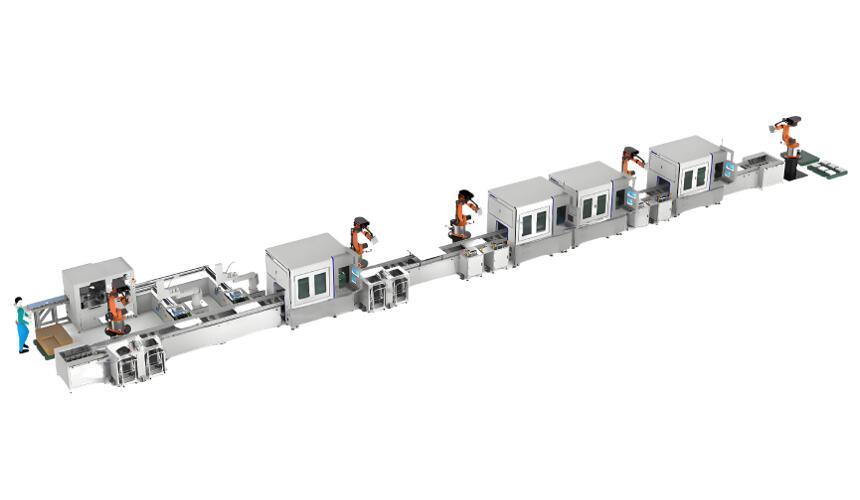

1.The driver automation production line is a solution tailored to customer needs. The production line realizes functions and applications such as brush heat dissipation, manual installation of support columns, assembly of upper and lower plates, insulation hose assembly machine, screw machine, burning, withstand voltage test, defective product cache repair, FCT, defective product cache repair, dispensing, aging, finished product testing, automatic shell assembly machine, assembly of waterproof rubber rings, air tightness detection, etc.;

2.Each PCB board needs to be laser-printed with a corresponding QR code;

3.The workstations in the production line that need to bind the workstation information to the product need to import a barcode scanner. When the product enters the workstation, the product is scanned and confirmed;

4.After the corresponding workstation completes the process of the product, the corresponding information is bound to the product;

5.Each workstation aggregates the information to the industrial computer end, and the system processes the information obtained and uploads it to the database for storage;

6.When tracing the product later, the information of each process station of the product can be retrieved by scanning the QR code on the product to facilitate confirmation of the problem.

Performance Characteristics

Highly automated: It realizes the automation of the entire process from parts loading, assembly to testing and sorting, reduces manual intervention, improves production efficiency and consistency of product quality, and reduces labor intensity and human errors.

High precision and high reliability: The use of advanced assembly and testing technology can ensure the assembly accuracy and test accuracy of the driver, improve the reliability and stability of the product, and meet the strict requirements of the automotive industry for the quality of parts.

Production flexibility: The production line can adjust the program and replace the fixtures according to different models and specifications of automotive drivers. It has strong flexibility and adaptability and can quickly respond to changes in market demand.

Data traceability: It has a complete data acquisition and management system that can record the production data and test results of each driver, realize the traceability of product quality, and facilitate the monitoring and optimization of the production process.

Application Range

It is mainly used in the production workshops of automobile manufacturers for the production and quality inspection of various types of automotive drivers, including power steering drivers, window lift drivers, etc. for traditional fuel vehicles, and motor drivers for new energy vehicles. It can also be used in automotive parts manufacturers to provide high-quality driver products for automobile manufacturers.

—————————————————————————————————————————————————————————

Hello! The above product information only lists some of the main test functions. All items supported by the equipment are not listed in detail here.

If you need to obtain customized solutions or company introduction materials, please contact mobile phone & WeChat: +86 18033069200

Click the picture below to view more customer cases