Introduction

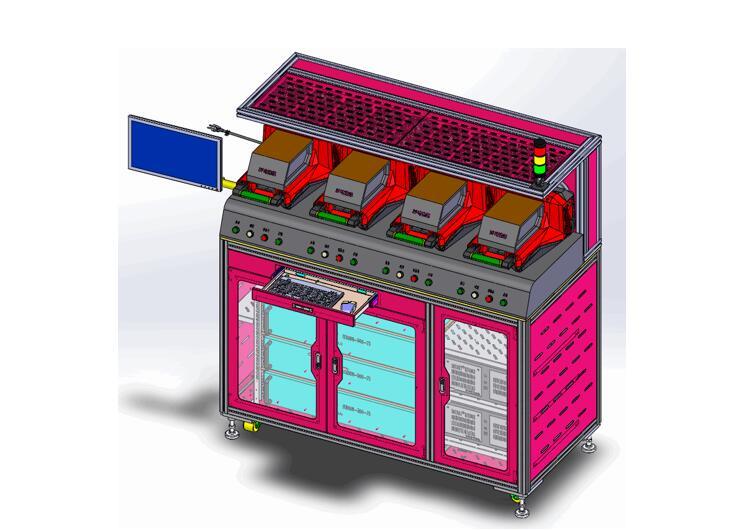

1. The batteries are arranged as 10X13=130/box;

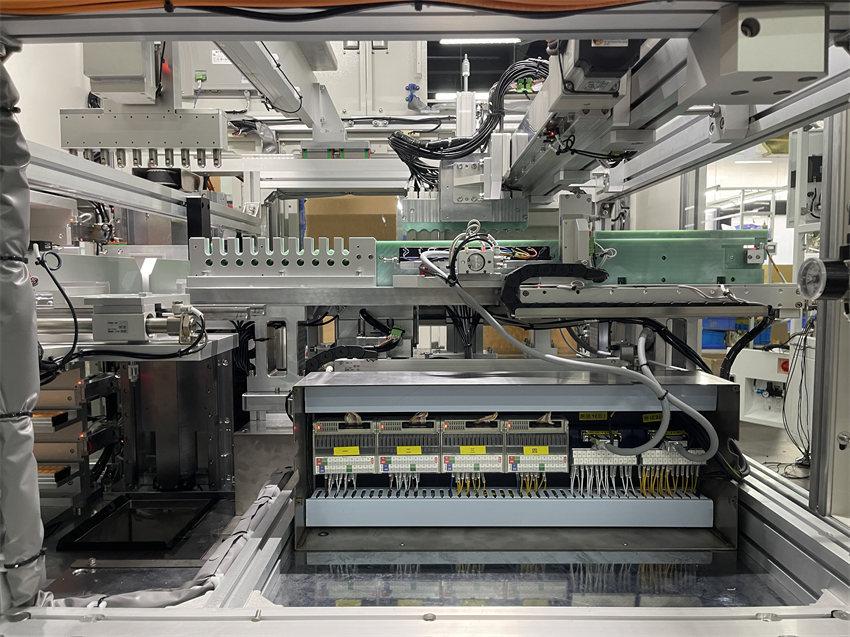

2. There are 4 channels (4 boxes) in the loading area at the entrance of the equipment. 10 batteries are grabbed each time, and the grabbing position of the battery can be selected;

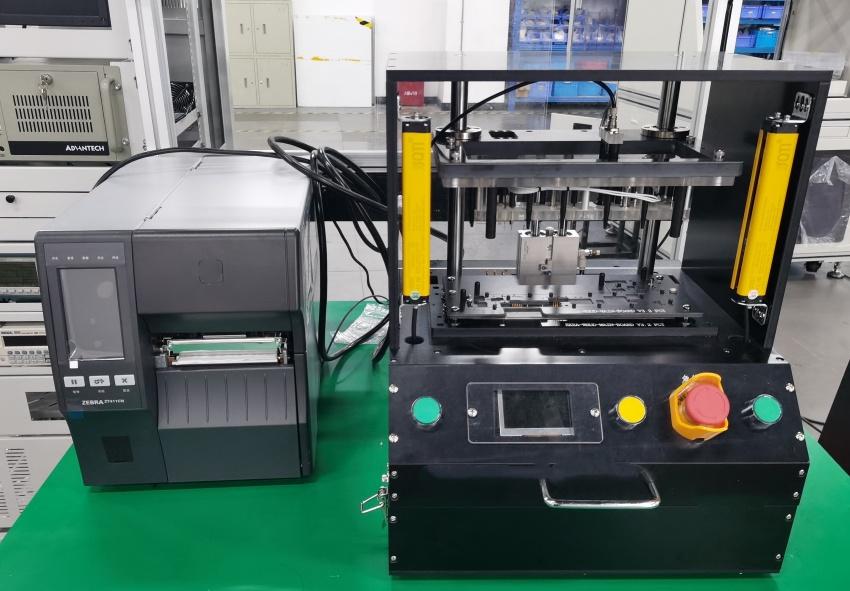

3. Battery internal resistance value/voltage value test, voltage balance value test;

4. Automatic loading of battery cells and brackets, sucking of battery cells, and automatic loading into brackets; battery cell internal resistance performance test, polarity detection;

5. The internal defective area of the equipment is divided into 2, the code scanning defective area and the test defective area, and each area can store 10 batteries;

6. When grabbing the battery, in order to prevent the blister box from being lifted, the battery box needs to have a clamping structure.

—————————————————————————————————————————————————————————

Hello! The above product information only lists some of the main test functions. All items supported by the equipment are not listed in detail here.

If you need to obtain customized solutions or company introduction materials, please contact mobile phone & WeChat: +86 18033069200

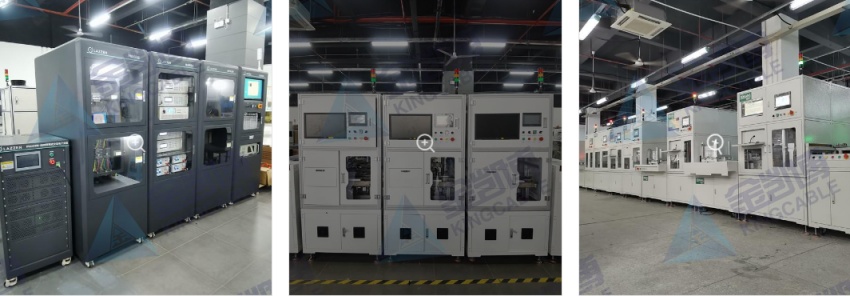

Click the picture below to view more customer cases