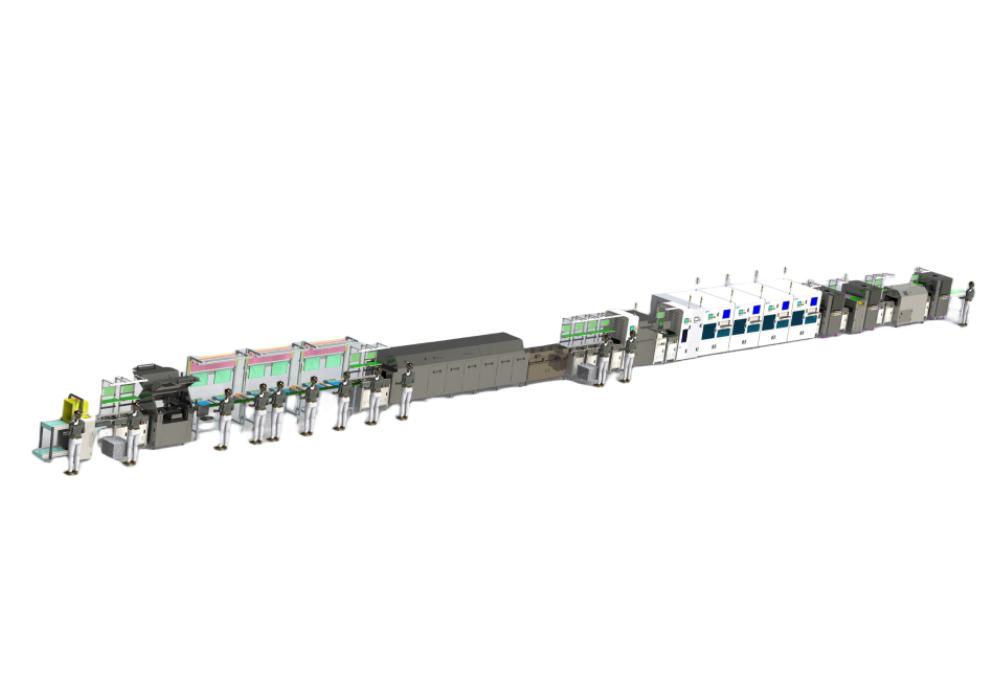

DIP Production Line Introduction

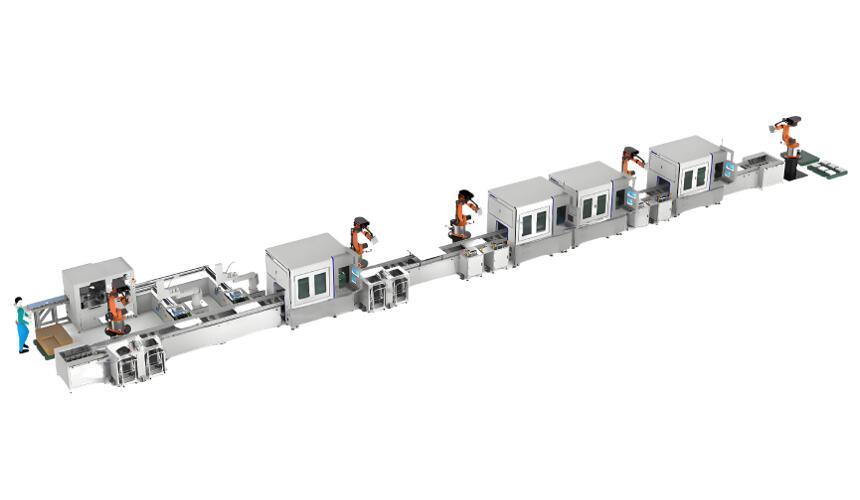

The line is a highly integrated and highly automated PCBA production and processing system that integrates multiple key links such as DIP process production, glue filling and curing. After completing automatic loading, plug-in, wave soldering, AOI inspection, ICT, FCT, board separation and other operations are carried out in sequence. Then, defective products are screened out through the inspection link, and good products enter the fully automatic glue filling and curing line. At the glue filling station, the control board is accurately positioned, and the automatic glue filling machine fills the glue according to the set amount and path. The control board that has completed the glue filling enters the curing equipment. After the corresponding curing process, the reflow finished product is output. The automated process greatly reduces manual intervention and significantly improves production efficiency to meet large-scale production needs.

Production line function

1. Automatic board loading and plug-in: realize automatic special-shaped plug-in, manual plug-in and other functions to reduce manual operation;

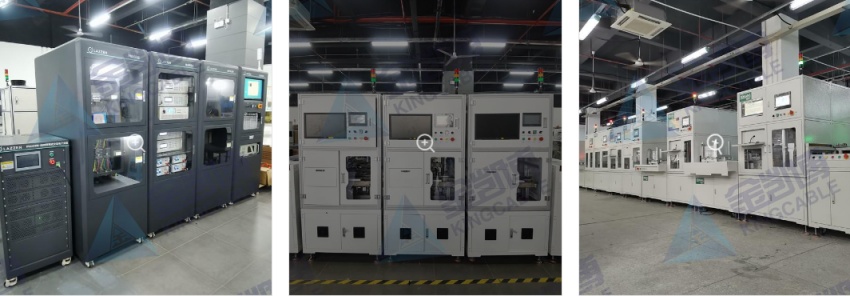

2. Welding and inspection: integrate wave soldering, online AOI, ICT, FCT and other equipment to ensure welding quality and functional performance;

3. Gluing and curing: equipped with fully automatic glue filling machine and curing furnace to realize the automatic operation of key processes such as glue filling and curing;

4. PLC control and MES docking: adopt PLC automatic control, support docking with MES system, upload production data in real time, and facilitate production management and quality traceability;

5. Visual system: equipped with visual camera system, automatically identify product model and glue filling position, and ensure glue filling accuracy;

6. Fast production change: support fast replacement of fixtures, reduce production change time, and improve production flexibility;

7. Multi-station operation: support multi-station ICT+FCT testing to improve testing efficiency;

8. Production data collection: real-time collection of production data, including production quantity, equipment abnormalities, etc., support data visualization analysis;

9. Quality traceability: realize the traceability of the production process through code scanning and data recording.

Application Industry

This line is widely used in the production of home appliance PCBA, such as the control board production of washing machines, air conditioners, refrigerators and other home appliances. In addition, it can also be expanded to automotive electronics, consumer digital, drones, medical products and other fields. This line reduces manual operations, improves production speed and product delivery capabilities, reduces labor costs and production floor space. Through high-precision detection and automated repair functions, it ensures product consistency and stability.

—————————————————————————————————————————————————————————

Hello! The above product information only lists some of the main test functions. All items supported by the equipment are not listed in detail here.

If you need to obtain customized solutions or company introduction materials, please contact mobile phone & WeChat: +86 18033069200

Click the picture below to view more customer cases